Cutting Board Info/Care

-How To Make Your Board Last For Generations-

Maintain Your Cutting Board

Seasoning the board- Apply FDA mineral oil heavily to the board everyday on all sides for a week,

then at least one day a week for a month, then at least once a month or more depending on usage. Always set your board on a side edge to allow the top and bottom to soak the oil in equally. You cant hurt it by oiling to much. If it appears dry at all oil is needed. A mix of bees wax and oil is a great way

to keep your board smooth and well coated. After cutting on a wooden cutting

board, it can generally be cleaned with just a damp cloth and mild soap. Always

wash both sides to prevent issues from uneven water absorption. Meat slicing

should be done on a separate board from vegetables to prevent bacteria

contamination. After washing, pat your wooden cutting board dry with a cloth and

allow it to air dry on the counter. Make sure to place the board standing on its

edge so that all sides dry evenly (doing so will prevent the board from warping

Never place your board in a dishwasher or completely submerged in water. When

placing the board flat on a countertop or such ,be sure the surface is

completely dry as to prevent the board from absorbing moisture in and cracking.

When storing your board placing it on edge is the best option.

If the board gets heavily scratched or has a rough feel from washing, it can be

sanded smooth again with 220 grit or finer sand paper . The rough feeling occurs from what is called grain raising and this occurs most noticeably right after washing the board or cutting juicy foods on it. Why? The wood swells and creates a uneven micro surface from the moisture. To remedy this its best to wait until you wash it a few times to further raise the grains and sand with 220grit. After sanding and cleaning, apply a fresh coat of food-grade mineral oil or butcher block conditioner. We actually do a step here at the shop to raise the grains and sand smooth before they leave but real hardwoods with a food safe finish still manage to grain raise over time. Similar to grain raising is raised ridge board slats described below.

Feeling raised ridges in the board? The ridges you're feeling are from the wood swelling/drying from the different humidity levels. Since there are so many cuts of wood in these blocks they don't all shrink and expand at the exact same rate. Each one is a slight different fiber density even if it was cut from the same board initially. We suggest seasoning the board as mentioned here, then after seasoning wash the board a few times to further raise the wood grains. This way it will save the need to sand more later. A good 220grit sandpaper will do the job and if available an orbital sander works fantastic for sanding the end grains. 220 is really the highest grit you will want to go otherwise it will be difficult to get the oils into the board later when needed again. Though neither grain raising or raised ridges will hurt the overall use of the board its just nice to have a super smooth cutting board to clean & feel.

then at least one day a week for a month, then at least once a month or more depending on usage. Always set your board on a side edge to allow the top and bottom to soak the oil in equally. You cant hurt it by oiling to much. If it appears dry at all oil is needed. A mix of bees wax and oil is a great way

to keep your board smooth and well coated. After cutting on a wooden cutting

board, it can generally be cleaned with just a damp cloth and mild soap. Always

wash both sides to prevent issues from uneven water absorption. Meat slicing

should be done on a separate board from vegetables to prevent bacteria

contamination. After washing, pat your wooden cutting board dry with a cloth and

allow it to air dry on the counter. Make sure to place the board standing on its

edge so that all sides dry evenly (doing so will prevent the board from warping

Never place your board in a dishwasher or completely submerged in water. When

placing the board flat on a countertop or such ,be sure the surface is

completely dry as to prevent the board from absorbing moisture in and cracking.

When storing your board placing it on edge is the best option.

If the board gets heavily scratched or has a rough feel from washing, it can be

sanded smooth again with 220 grit or finer sand paper . The rough feeling occurs from what is called grain raising and this occurs most noticeably right after washing the board or cutting juicy foods on it. Why? The wood swells and creates a uneven micro surface from the moisture. To remedy this its best to wait until you wash it a few times to further raise the grains and sand with 220grit. After sanding and cleaning, apply a fresh coat of food-grade mineral oil or butcher block conditioner. We actually do a step here at the shop to raise the grains and sand smooth before they leave but real hardwoods with a food safe finish still manage to grain raise over time. Similar to grain raising is raised ridge board slats described below.

Feeling raised ridges in the board? The ridges you're feeling are from the wood swelling/drying from the different humidity levels. Since there are so many cuts of wood in these blocks they don't all shrink and expand at the exact same rate. Each one is a slight different fiber density even if it was cut from the same board initially. We suggest seasoning the board as mentioned here, then after seasoning wash the board a few times to further raise the wood grains. This way it will save the need to sand more later. A good 220grit sandpaper will do the job and if available an orbital sander works fantastic for sanding the end grains. 220 is really the highest grit you will want to go otherwise it will be difficult to get the oils into the board later when needed again. Though neither grain raising or raised ridges will hurt the overall use of the board its just nice to have a super smooth cutting board to clean & feel.

Why Wood Is The Better Choice For A Cutting Board-http://www.akitchen.com/blog/2013/11/22/on-cutting-boards-plastic-vs-wood-you-may-be-surprised/

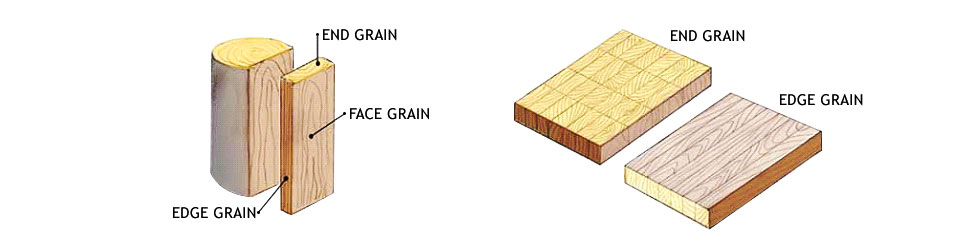

What is the difference? End vs Edge or Face

Layout info-

The majority of wood cutting boards you can buy today are edge or face grain design, meaning you are looking at the

wood grain along its length (direction of growth). With end grain boards, you are looking into the end of the grain, as if you are looking down into the top of a tree stump.

Both designs are just as functional and food safe, but end grain boards are far more durable and friendlier to your knife.

The old fashioned butcher blocks were always end grain design (chopping block) for a reason: to keep the knives much sharper.

Instead of crushing against the wood fibers, the blade goes between them much like cutting into the end of a firm brush.

In a face grain board, think of wood fiber much like hair, as you cut across you break the fiber and those fibers

start to pop up from the board surface. With proper care, a face grain board will last many years, but an end grain board will last a life time.

wood grain along its length (direction of growth). With end grain boards, you are looking into the end of the grain, as if you are looking down into the top of a tree stump.

Both designs are just as functional and food safe, but end grain boards are far more durable and friendlier to your knife.

The old fashioned butcher blocks were always end grain design (chopping block) for a reason: to keep the knives much sharper.

Instead of crushing against the wood fibers, the blade goes between them much like cutting into the end of a firm brush.

In a face grain board, think of wood fiber much like hair, as you cut across you break the fiber and those fibers

start to pop up from the board surface. With proper care, a face grain board will last many years, but an end grain board will last a life time.

How To Disinfect A Wood Cutting Board

Sanitize With Vinegar

Using water and dishwashing detergent can weaken surface wood fibers on cutting boards and butcher block countertops. To disinfect and clean your wooden surfaces, wipe them instead with full-strength white vinegar after each use. The acetic acid in the vinegar is a good disinfectant, effective against such harmful bugs as E. coli, Salmonella, and Staphylococcus. When your wooden cutting surface needs deodorizing as well as disinfecting, spread some baking soda over it and then spray on undiluted white vinegar. Let it foam and bubble for five to ten minutes, then rinse with a cloth dipped in clean cold water.

Using water and dishwashing detergent can weaken surface wood fibers on cutting boards and butcher block countertops. To disinfect and clean your wooden surfaces, wipe them instead with full-strength white vinegar after each use. The acetic acid in the vinegar is a good disinfectant, effective against such harmful bugs as E. coli, Salmonella, and Staphylococcus. When your wooden cutting surface needs deodorizing as well as disinfecting, spread some baking soda over it and then spray on undiluted white vinegar. Let it foam and bubble for five to ten minutes, then rinse with a cloth dipped in clean cold water.

Hydrogen Peroxide Will Kill Bacteria.

Hydrogen peroxide is a surefire bacteria-killer—just the ally you need to fight the proliferation of bacteria on your cutting board, especially after you cut chicken or other meat. To kill the germs on your cutting board, use a paper towel to wipe the board down with vinegar, then use another paper towel to wipe it with hydrogen peroxide. Ordinary 3% peroxide is fine.dit.

Lemons Will Remove Odor

If your cutting board smells after you chop onions, crush garlic, cut raw and cooked meat and chicken, or prepare fish, get rid of the odor and help sanitize the cutting board by rubbing it all over with the cut side of half a lemon. You can also wash your cutting board in undiluted lemon juice from a bottle. See more uses for lemons.

Salt Will Deep Clean.

If you clean cutting boards and breadboards with soap and water, rub them afterwards with a damp cloth dipped in salt. The boards will be lighter and brighter in color. You can also create a paste of salt and lemon juice, and use it to deep clean your cutting board as needed.